New development compressor which is specifically designed for high-altitude oxygen concentrators

In June 2023, our company independently developed compressors for high-altitude oxygen concentrators .

The first we need to know the difference between high-altitude oxygen concentrators and ordinary oxygen concentrators in terms of compressors:

The environment in high-altitude areas is complex and harsh. Oxygen concentrators operate under harsh conditions such as high altitude, high electromagnetic, low air pressure, lack of oxygen, high cold, large temperature difference, and strong sandstorms. Therefore, high-altitude oxygen concentrators require compressors to meet the following requirements for working in high-altitude environments:

1. The plateau environment requires the compressor motor to have a higher insulation level and silicon steel material compared to ordinary plain motors, because the thin air in the plateau is not conducive to heat dissipation.

2. High altitude environments require compressor motors to have better heat dissipation compared to ordinary plain motors, so most motor casings add heat dissipation bodies.

4. High altitude environments require compressor motors to have a temperature resistance of -35℃to+60℃, while ordinary plain motors have a temperature resistance of -15℃to+60℃. Therefore, high altitude environments require compressor motors to undergo low-temperature -35 ℃ adaptive design treatment.

5. The plateau environment requires that the internal electromagnetic scheme of the compressor motor is completely different from that of ordinary plain motors, and high electromagnetic environment adaptability structural design is required.

6. The plateau environment requires special treatment to prevent condensation and freezing inside the compressor motor.

7. The working environment adaptability of the compressor piston ring is required to meet the requirements of -40℃ to+120℃ in high-altitude environments.

8. The working environment adaptability of the compressor operating bearings in high-altitude environments should meet the requirements of -40℃to+120℃

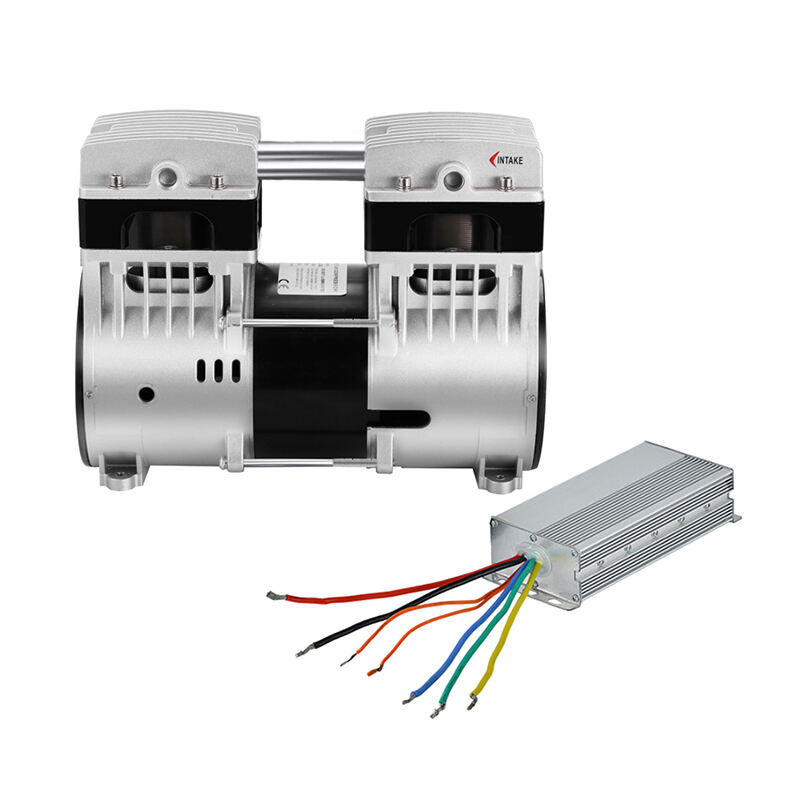

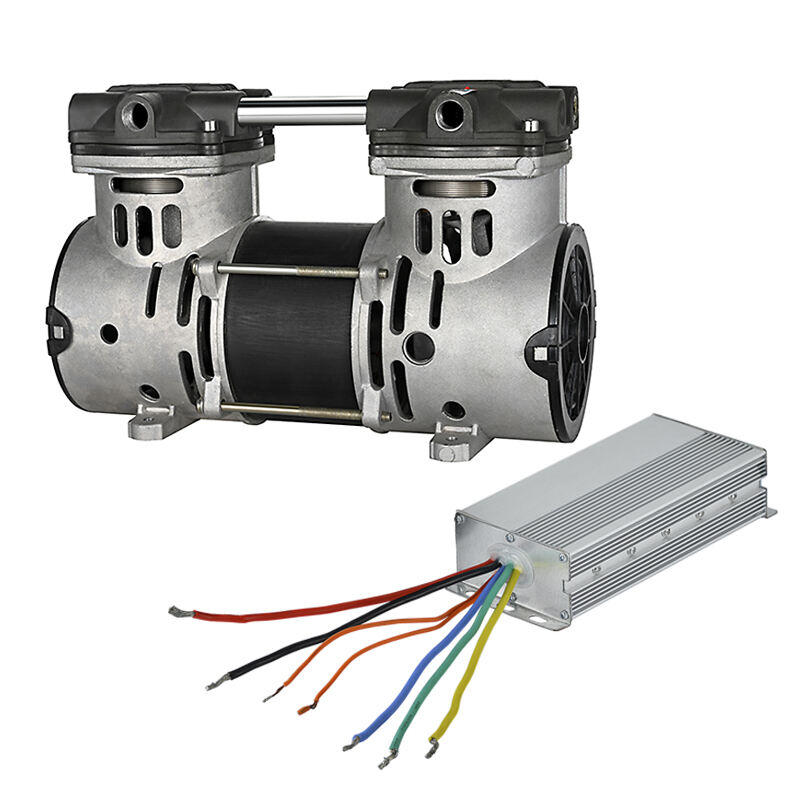

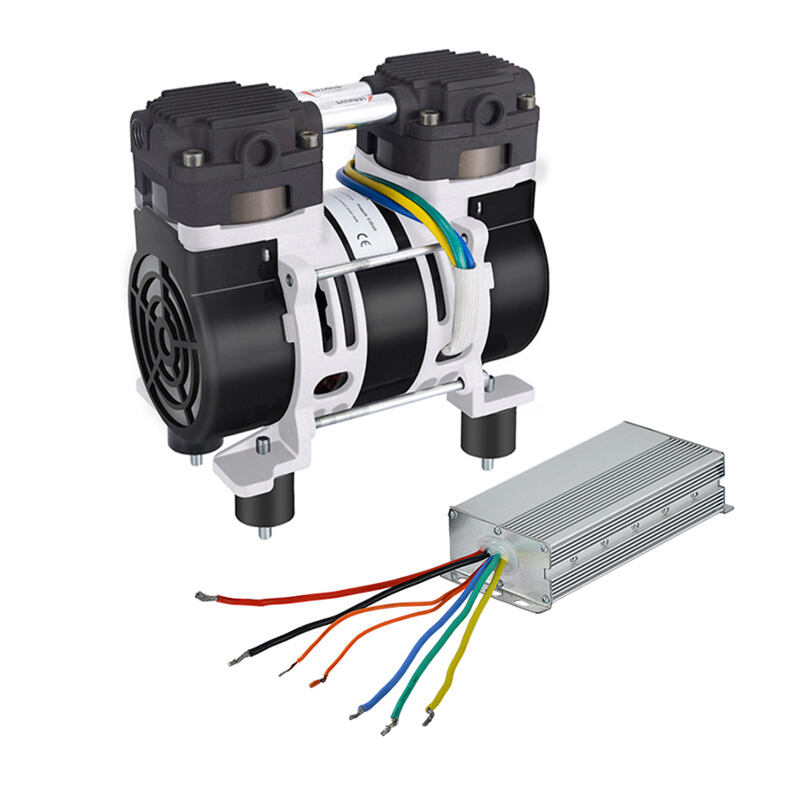

In June 2023, our company successfully developed the new HC0680A1-140/2-G compressor, which is specifically designed for high-altitude oxygen concentrators and can meet the needs of high-altitude use below 4000 meters

1. The leather bowl is made of imported polymer materials and processed domestically, with a working environment adaptability of -40 ℃ to+120 ℃, effectively improving the service life of the compressor in low-temperature environments.

2. The bearing adopts imported high and low temperature resistant bearings, with adaptability to working environments ranging from -40 ℃ to+120 ℃

3. The compressor adopts a super large flow rate of 140L/min to cope with the oxygen flow attenuation caused by air scarcity at high altitudes

4. The motor is independently developed by HCEM, with insulation of equal pole F pole, and the motor efficiency reaches 75%, effectively solving the problem of poor starting of compressors in high-altitude use.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

KA

KA

MN

MN