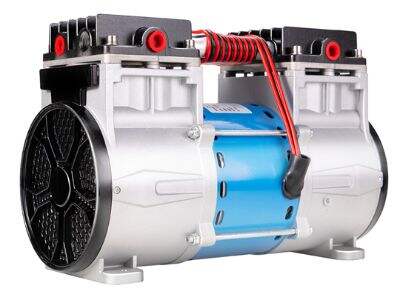

CNC machines are cool tools for making things with wood, metal, and more. Some time vacuum pump on a CNC router may face issues that needed to be resolved. Join us today to learn about some common problems with HCEM CNC router VACUUM PUMP, and solutions to help keep our machines running.

Cleaning and Maintenance of the Filters

The vacuum pump filters work as a kind of strainer, they help to collect dirt and dust in order to avoid making your pump full of dirt. Once the filters are clogged, the pump may not function as well, making it more difficult for the machine to hold material in position when cutting or engraving. This way we need to clean the filters frequently. Use a soft brush or cloth to carefully clean excess dirt, and swap out filters if they’re old or damaged. We can make the CNC router vacuum pump types more effective by keeping the filters clean.

Ventilation and Cooling: Why It Matters

Machines also require some cool-down time to optimize their performance, just like we do. Proper ventilation and cooling systems prevent the vacuum pump from overheating and the consequent breakdown. Ensure surrounding areas of the CNC router are free of obstructions that would restrict airflow. Use fan or air conditioner also during processing to cool machine. Heating and cooling are crucial to our vacuum pumps running longer without costly repairs.

Finding and Fixing Air Leaks

This is a tricky one, as air leaks are problematic and will reduce suction on the vacuum pump. Check for gaps, holes, or loose connections in the hoses, pipes, or components of the vacuum system. Seal these areas with tape, glue or new parts to prevent air from leaking out. Quickly fixing leaks helps us to maintain the suction level on our CNC router and to hold materials in place while cutting or engraving.

Using Suction Levels to Solve Problems

the suction on the CNC router is weak or unsteady If the suction on the CNC router appears to be weak or unsteady, there are a few reasons for this. Start by checking the filters to ensure they are clean or need to be replaced. Next, examine the hoses and connections for potential air leaks that could be contributing to the suction loss. And ensure that nothing can block the vacuum pump. We can diagnose the low suction and fix it by checking these typical issues.

When to Seek Assistance with the Vacuum Pump?

Like any machine, vacuum pumps require regular maintenance to run smoothly. If there are weird noises, it’s running too hot or it’s losing suction even after you got things cleaned, it may be time to have the pump serviced — or replace it. For this, contact a professional technician or our HCEM customer service team. Regular maintenance ensures that our CNC router performs at its best and produces quality projects.

Final words on equation of a CNC router vacuum pump maintenance micron chip. By looking at how to clean and maintain filters, provide adequate ventilation and cooling, locate and correct air leaks, diagnose suction issues, and call for help with the vacuum pump, we can keep our machines in top shape. And don’t forget to reach out to our HCEM team anytime — if you need support with your CNC router vacuum pump, we’re here for you. Happy crafting.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

HY

HY

AZ

AZ

KA

KA

MN

MN