An air compressor pump is something that most of us use when we are trying to blow up a balloon, fill our tires with some much needed air. We bought this pump, which has been so helpful enabling us to do very many things that require air pressure. So, today we are going to be discussing air compressor pumps from HCEM. Let's check out how they work, later we will find the best one for our needs and also take care of them that keep help to running well in a long time.

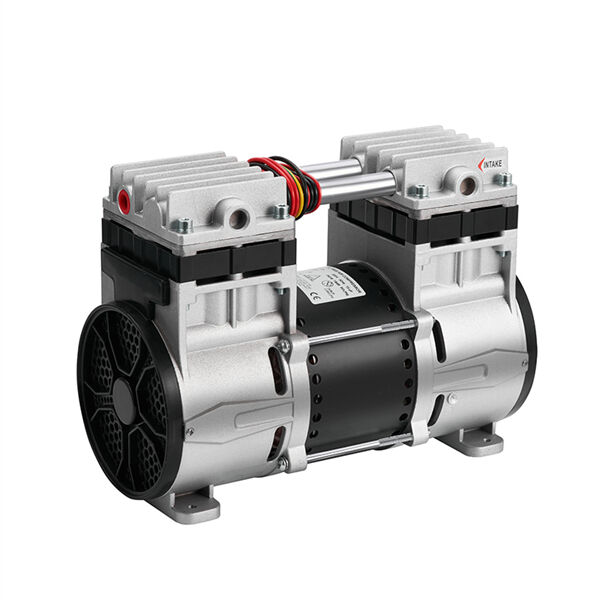

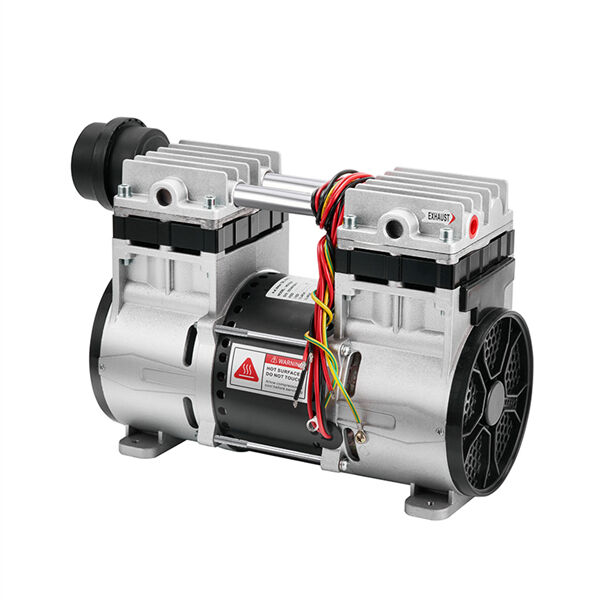

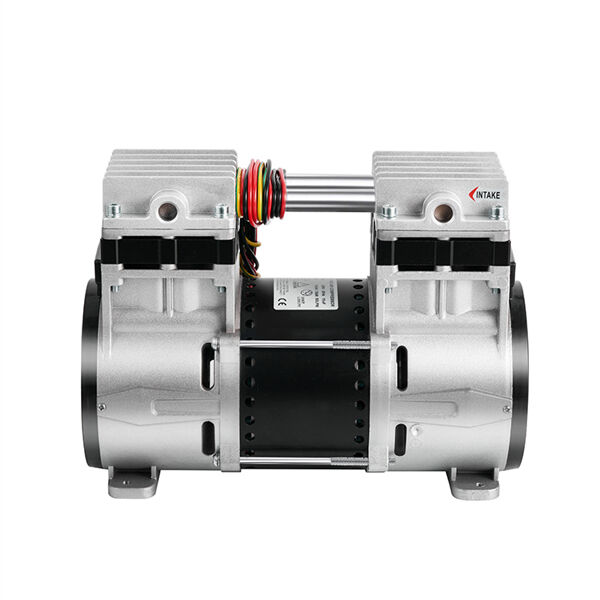

These pumps are also called positive displacement blowers since they contain components that move with the airflow, as opposed to centrifugal air compressors whose parts rotate and expel gas using impellers. Reciprocating pumps rely on pistons for over-compression of air by reducing volume and increasing pressure generated through crankshafts turning a small drive motor while rotary screw type units utilize two intermeshing screws rotating together pulling in fluid then pushing it out maintenance free with less heat exhaust than oil-free or water cooled designs. The kind of you choose relies on the specific task in hand and how much air pressure is required so opt for auto air compressor from HCEM.

The size of the motor is another crucial factor. If you need to use more than one tool at a time or require significant air volume in short order, then the larger motor can push higher amounts of air through the pump like portable compressor from HCEM.

Air compressor pumps serve a pivotal role in numerous industries like construction, manufacturing and automotive repair. Compressors allow employees to power tools like high-pressure air tools, this not only makes jobs easier but saves time for completion as well. For instance, if you have to bang in many nails promptly and over a wide area like in tiles or roof fixing, an air compressor pump-driven nail gun will be more preferable because it removes the effort of hammering each fastener by hand. Air compressor pumps are also widely used to power painting tools, which lends itself to faster and more consistent paint application on surfaces so opt for AC AIR COMPRESSOR PUMP.

Falling short of perfection—Make sure to regularly check everything against leaks from connections and hoses up. Leaks can cause your pump to perform poorly which directly results in decreased performance and efficiency. Once you see any leaks, fix them right away to preserve the effectiveness of your DC AIR COMPRESSOR PUMP.